At Action Metals, we encounter a wide array of metals daily, all with their own unique properties and applications. Understanding the fundamental differences between non-ferrous and ferrous metals is crucial for efficient recycling and resource management.

Let’s explore these categories, dig into their distinct characteristics, and uncover why this knowledge should matter to us all.

The Magnetic Divide

Ferrous metals are characterized by their iron content, which imparts magnetic properties and makes them susceptible to rust and corrosion. Steel, cast iron, and wrought iron are common examples. The presence of iron significantly influences their strength, durability, and applications.

Iron | Magnetic and Corrosive

The iron content in ferrous metals is responsible for their magnetic attraction. This property is vital in various industrial applications, such as electromagnetic machinery and magnetic separation processes. However, iron also makes these metals vulnerable to rust and corrosion, especially in humid or wet environments.

Strong and Durable

Ferrous metals, particularly steel, are renowned for their strength and durability. They form the backbone of numerous industries, including construction, automotive, and manufacturing. Steel beams support skyscrapers, and steel components are essential in vehicle manufacturing.

Cost-Effective

Iron is one of the most abundant elements on Earth, making ferrous metals relatively cost-effective. This affordability contributes to their widespread use in various applications, from everyday tools to large-scale infrastructure projects.

Magnetic Separation

The magnetic properties of ferrous metals simplify their recycling process. Magnetic separators are used to efficiently separate these metals from other materials, ensuring efficient recovery and reuse.

Non-Magnetic Metals

Non-ferrous metals, as the name suggests, lack iron content and are therefore non-magnetic. They are generally more resistant to corrosion and often possess unique properties, such as high conductivity and malleability. Examples include aluminum, copper, brass, and lead.

Corrosion-Resistant

Non-ferrous metals exhibit excellent corrosion resistance, making them ideal for applications exposed to harsh environments. Aluminum, for example, is widely used in outdoor applications due to its resistance to rust.

Conductive and Malleable

Many non-ferrous metals, such as copper and aluminum, possess high electrical and thermal conductivity. Copper wiring is essential in electrical systems, and aluminum is used in heat sinks and electronic components. Their malleability allows them to be easily shaped and formed.

Lightweight and Beautiful

Aluminum’s lightweight properties make it a popular choice in the aerospace and automotive industries. Non-ferrous metals are also valued for their aesthetic appeal, often used in decorative applications and architectural designs.

High Value

Many non-ferrous metals retain high monetary value when recycled. This creates strong economic incentives for collection and processing. Because of this, it is very important to recycle these materials.

The Implications for Recycling and Sustainability

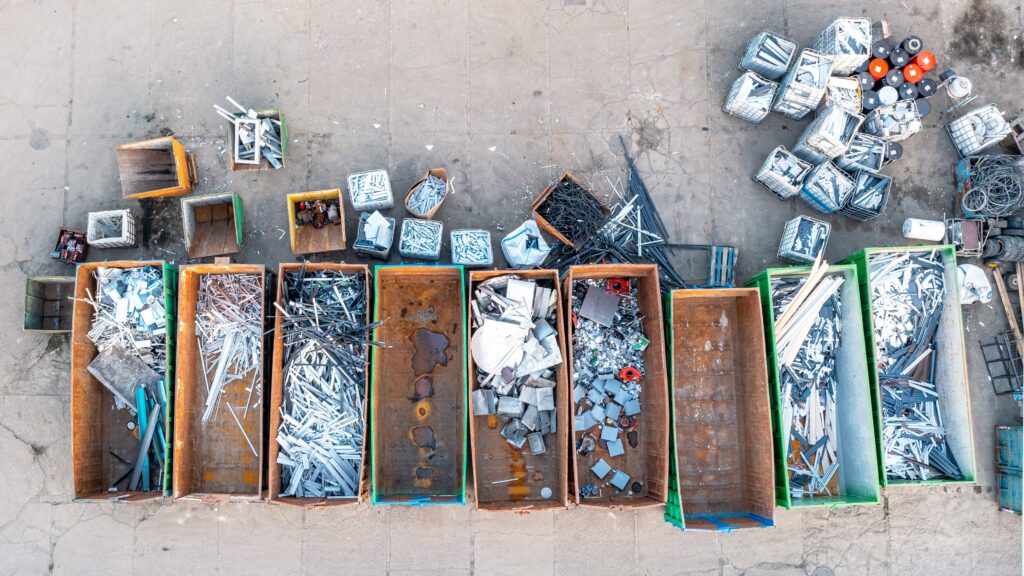

Understanding the differences between non-ferrous and ferrous metals is essential for efficient recycling and resource management. Proper sorting and separation of these metals are crucial for maximizing recovery and minimizing waste.

Efficient Sorting

Accurate sorting and separation of non-ferrous and ferrous metals are vital for efficient recycling. Magnetic separators are used to separate ferrous metals, while other methods are employed for non-ferrous metals. This ensures that valuable materials are recovered and reused.

Resource Conservation

Recycling metals reduces the need for virgin material extraction, conserving natural resources and minimizing environmental impact. By understanding the properties of different metals, we can optimize recycling processes and promote sustainability.

Economic Benefits

Recycling metals creates economic value by recovering valuable materials and reducing waste disposal costs. Efficient recycling practices contribute to a circular economy, where resources are reused and repurposed.

Environmental Stewardship

Proper metal recycling helps to prevent harmful substances from entering the environment. It also reduces energy consumption, and pollution when compared to creating new materials.

Call on Action Metals for Your Ferrous and Non-Ferrous Metals Recycling Needs

We encourage you to partner with Action Metals and contribute to our sustainable recycling efforts. Contact us today to learn how you can benefit from our expertise in handling both non-ferrous and ferrous metals. Together, we can create a more sustainable future.

FAQ

Q: What is the main difference between non-ferrous and ferrous metals?

Ferrous metals contain iron and are magnetic, while non-ferrous metals lack iron and are non-magnetic.

Q: Why is it important to separate non-ferrous and ferrous metals for recycling?

Proper separation ensures efficient recovery, maximizes resource conservation, and minimizes waste.

Q: What are some common examples of non-ferrous metals?

Common examples include aluminum, copper, brass, and lead.

Q: What are the benefits of recycling non-ferrous metals?

Recycling non-ferrous metals conserves resources, reduces energy consumption, and creates economic value.

Q: How does Action Metals contribute to sustainable metal recycling?

Action Metals utilizes efficient sorting and separation techniques to maximize metal recovery and promote environmental stewardship.